Responsible for the facility

Sadilov Valentin

tel. +7 (496) 216-42-41

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Main research areas

1. Investigation of the structure of thin films on a solid substrate.

2. Non-polarized neutron beam mode: restoration of the parameters of the efficient layer thickness, roughness of the boundaries between the layers and the free surface, determination of the neutron-optical density of the layer materials.

3. Polarized neutron beam mode: estimation of the magnetic properties of the structure of the layers on the substrate surface, the type of magnetic ordering of the layers in an external magnetic field, magnetic parameters - the efficient thickness of the layers, the roughness of the boundaries between the layers and the free surface, the determination of the neutron-optical density of the materials of the layers.

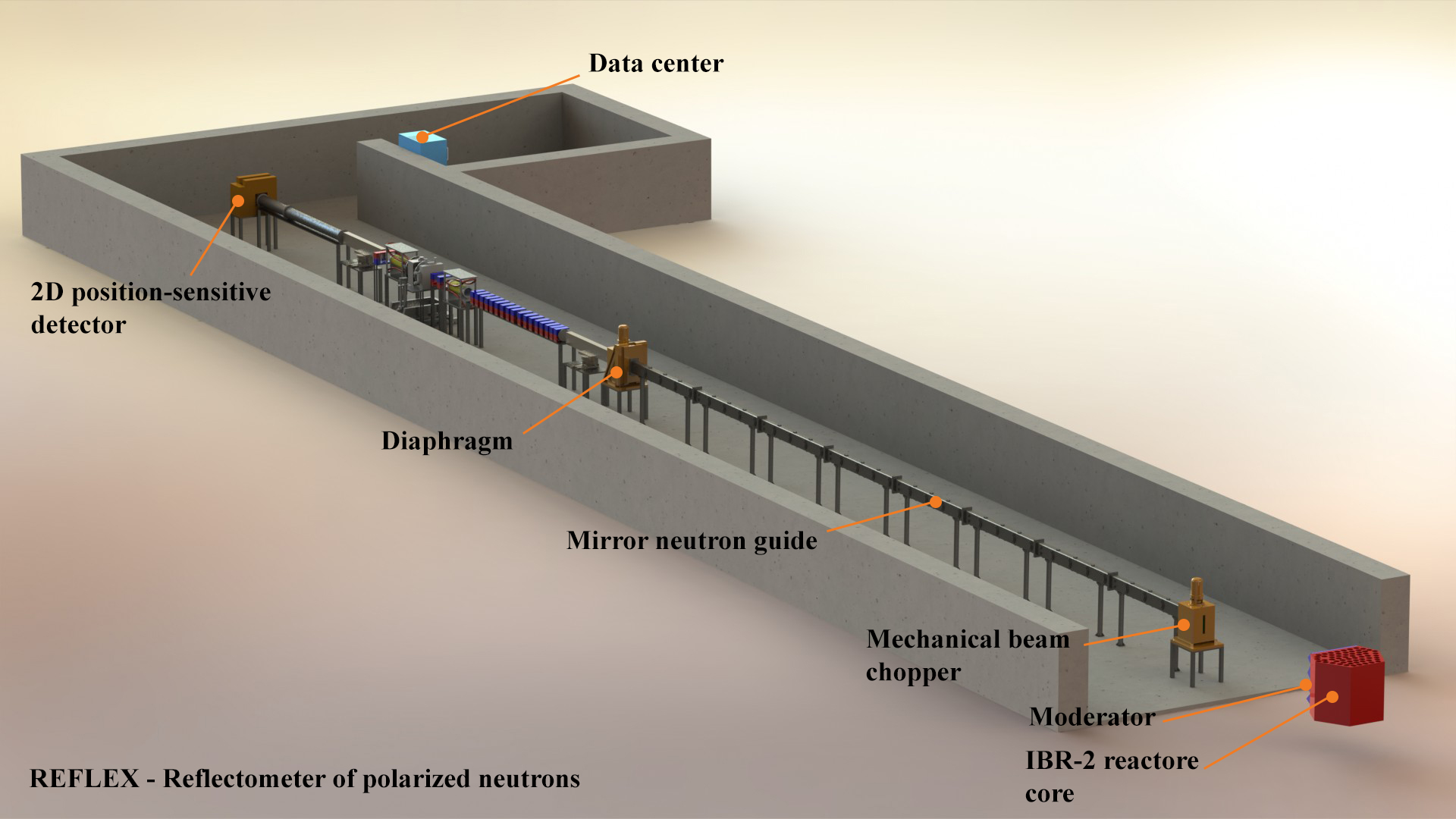

Facility layout

Main view of facility

Main view of facility

Description of REFLEX

Reflectometer of polarized neutrons REFLEX is used for time-of-flight investigations of thin-film magnetic and non-magnetic nanostructured objects at room temperature. The great path length provides the possibility of measurements with high temporal and angular resolution.

In addition to scientific research at the REFLEX facility, scientific and methodological investigations on diagnosing the quality of neutron-optical structures are carried out, new techniques with polarized neutrons are studied and developed.

The REFLEX reflectometer is positioned on the beamline No.9 of the IBR-2 reactor.

Functionally and structurally, the spectrometer can be divided into component parts: the beam former, the sample environment and the detector system.

The first section is designed to extract the beam from the ring corridor to the experimental hall and to filter the radiation, i.e. splitting off the thermal (and cold) neutron flux from fast neutrons and other types of radiation breaking away from the window and leading to the reactor core.

A drum-type mechanical beam chopper is installed in the ring corridor at a distance of 5 meters from the moderator. The chopper transmission window is 20–25 Å that is required for the transmission of the entire thermal spectrum of neutrons and delay of satellite pulses, as well as the background of the reactor.

The neutron beam is produced using a mirror neutron guide 26 m long, with a cross section of 10 mm×80 mm. The neutron guide possesses a linear part (3 m) and a curved part 22.8 m long. The cross section of the neutron guide is 10mm×80mm. The radius of curvature of the neutron guide is 2844 m that allows to divert the neutron beam at the output at 10 mm away from the initial direction specified by the head. Thus, the neutron guide blocks the optical visibility of the moderator. Reflection of the beam of thermal neutrons apart provides a significant reduction in the high-energy (fast) neutron flux. The housings of the neutron guides are hermetically sealed and assembled together. In the common chamber of the housing, a vacuum at the level of 4×10-3 (Torr) is maintained.

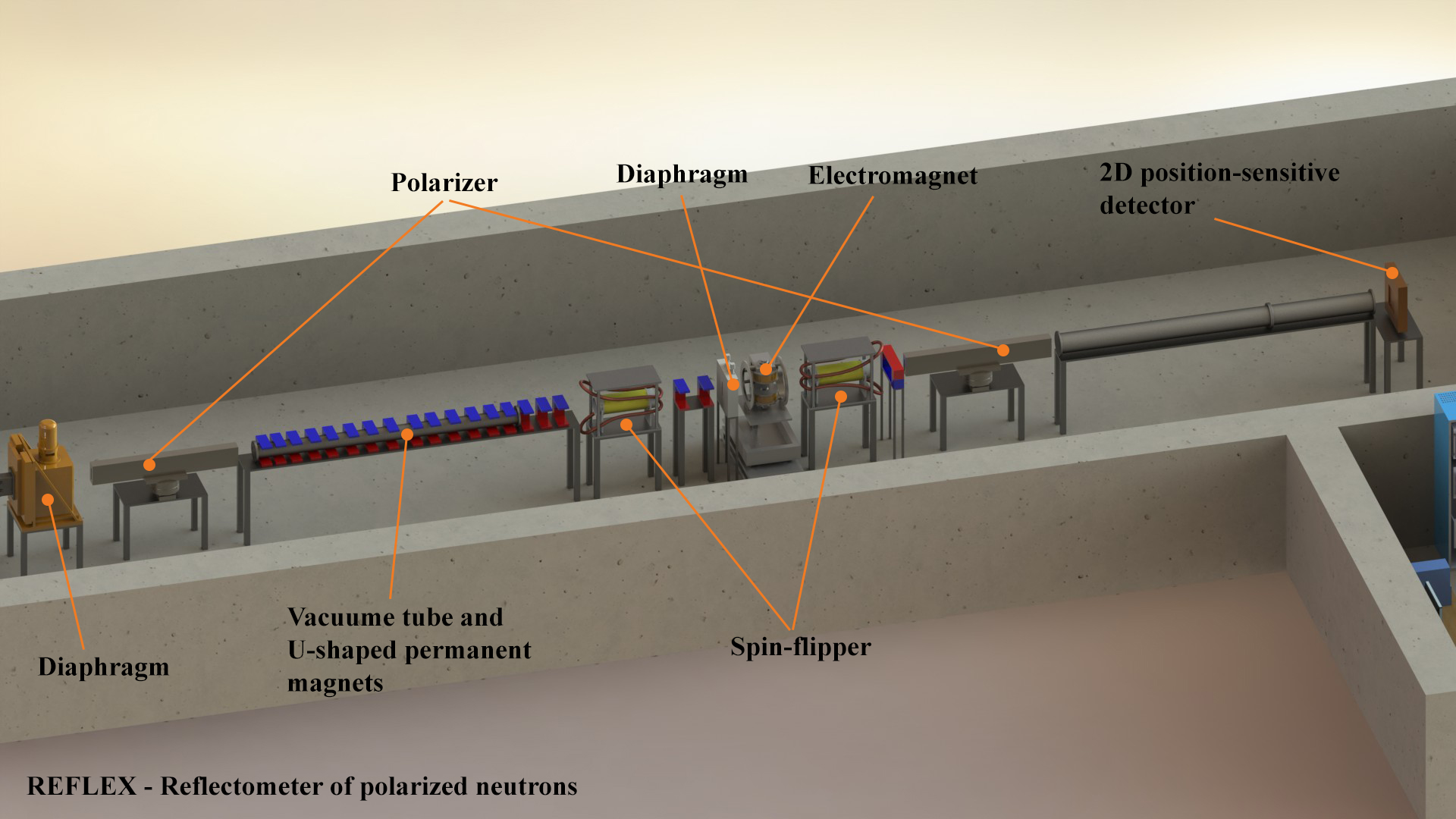

Right behind the neutron guide, an automated massive slit diaphragm is positioned to suppress the waste of the fast neutron direct beam and divergent thermal neutrons. The gap between the shutters and the transverse position of the slit is controlled remotely from the computer. Together with the diaphragm, a second drum-type beam chopper (the so-called "λ-chopper") is installed that can be used to split off neutrons that do not fall within the operating spectral range of 1-11 Å.

At the basis 28 m from the moderator, behind the diaphragm, a neutron beam polarizer 70mm×120mm×570mm is positioned, transmission type polarizer (SwissNeutronics AG), V-shaped silicon wafers with [Fe/Si] structure and m=5 index. The mechanical body of the polarizer with a magnetic system inside is mounted on two automatic platforms: rotary (0-360°) and linear (160 mm). Thus, the position of the polarizer can be adjusted remotely and, if required, can be inserted/extracted from the beam.

After the polarizer, a path length is required for the spatial separation of beams of opposite polarization. On REFLEX, this path length is equipped with a vacuum-processed aluminum tube with a diameter of 20mm and a length of 3.4 m. The ends of the tube are closed with 1mm aluminum membranes. The tube is positioned inside an assembling beamline, consisting of U-shaped permanent magnets to produce an external leading magnetic field of the same direction as implemented in the polarizer. The field is required for the maintenance of the neutron beam polarization.

Behind the vacuum-processed tube, the first RF adiabatic spin rotator is positioned. After the spin-flipper, there is a platform for a permanent magnet of the leading field and a frame - a place for installing a collimating diaphragm (JJ X-ray company) with four independent cadmium-coated shutters. Aperture control is remote. The movement of shutters allows to install a gap for the neutron beam with an accuracy of 0.002 mm. The "JJ X-ray" diaphragm is entirely manufactured of non-magnetic materials and is designed for use in polarized neutron beam conditions.

Functional assemblies producing a beam with a length of 35.5 m extract the neutron beam to the measurement room where right behind the “JJ X-ray” collimation diaphragm the technical components of the sample environment are positioned.

The sample environment is represented using an electromagnet mounted on a massive steel table. The steel table platform is equipped with a swivel mechanism (amplitude 0-50 mrad) and a cross-shift mechanism (stroke 0-250 mm). Both movement and rotation are controlled remotely from a computer.

Between the poles of the electromagnet, a sample holder is horizontally positioned that is a branch tube connected by its outer end to a low-power air pump. Samples, plates and glasses are pressed against the end of the branch tube due to uncompensated atmospheric pressure.

After the sample table, a second RF spin flipper is installed, circled by permanent magnets to maintain the guiding magnetic field. Behind it, there is a table for a polarization analyzer (SwissNeutronics AG). The analyzer's magnetic supermirrors ([Fe/Si], m=5) allow to operate both in the reflection mode and in neutron transmission. The analyzer 550mm long is mounted on a turntable (0-360°) and a transverse translator (0-200mm) (StandaLtd.). The polarization analyzer can be remotely configured, inserted and extracted from the beam.

The detector system is positioned at a distance of 6.0–6.1 m from the position of the sample. Gas-discharge detectors are available for the experiment: a 2-D position-sensitive (PSD) 3He detector with a window of 200 mm×200 mm (distance from the sample is 6.01 m and from the moderator - 43.1 m) manufactured by DSC FLNP JINR and a pair of single 3He detectors (Helium-18/80-3.0/L” Scientific-Production Firm CONSENSUS) (distance from the sample - 5.885 m). Single counters are installed on linear translators from StandaLtd (transverse displacement is 0-203 mm) and the position-sensitive detector is positioned in a massive housing of boron-polyethylene plates (inside lined with Cadmium sheets).

The acquisition and processing of primary signals along with the accumulation of data from the PSD is carried out using DeliDAQ 1.0. Single counters are serviced using the DTM system and processing units, as well as high-voltage power supply units, are positioned in a common vertical diaphragm outside the measuring area. Data accumulation control and subsequent visualization are implemented from a computer using the software package “Sonix” (technical support of DSC FLNP JINR).

Main characteristics Supermirror neutron guide 27 m, m=1.2; Transmission V-shaped resonator based on Fe/Si supermirror, m=5.0 2-D 200x200 mm2 gas-discharge He3 position-sensitive detector;

Beaming

Wavelength range, Å

1.4 - 10

Pulse transfer range, Å-1

0.001- 0.13

Neutron flux at sample position, s-1сm-2

105

Q-resolution, %

3 - 10

Max flight path (moderator-detector), m

43

Sample-detector distance, m

2 - 4

Min. sample size

10x10 mm2

Magnetic field at the sample, T

<0.4

Spin flippers

2 RF adiabatic spin flippers

Polarizer

Analyzer

Transmission, Fe/Si, m=5.0

Detector system

Sample environment

- Electromagnet

- Sample holder

References

no references