Neutron radiography and tomography (NRT)

Resposible for the facilty

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Main research areas

Facility layout

Main view of facility

Sample environment

Description of NRT

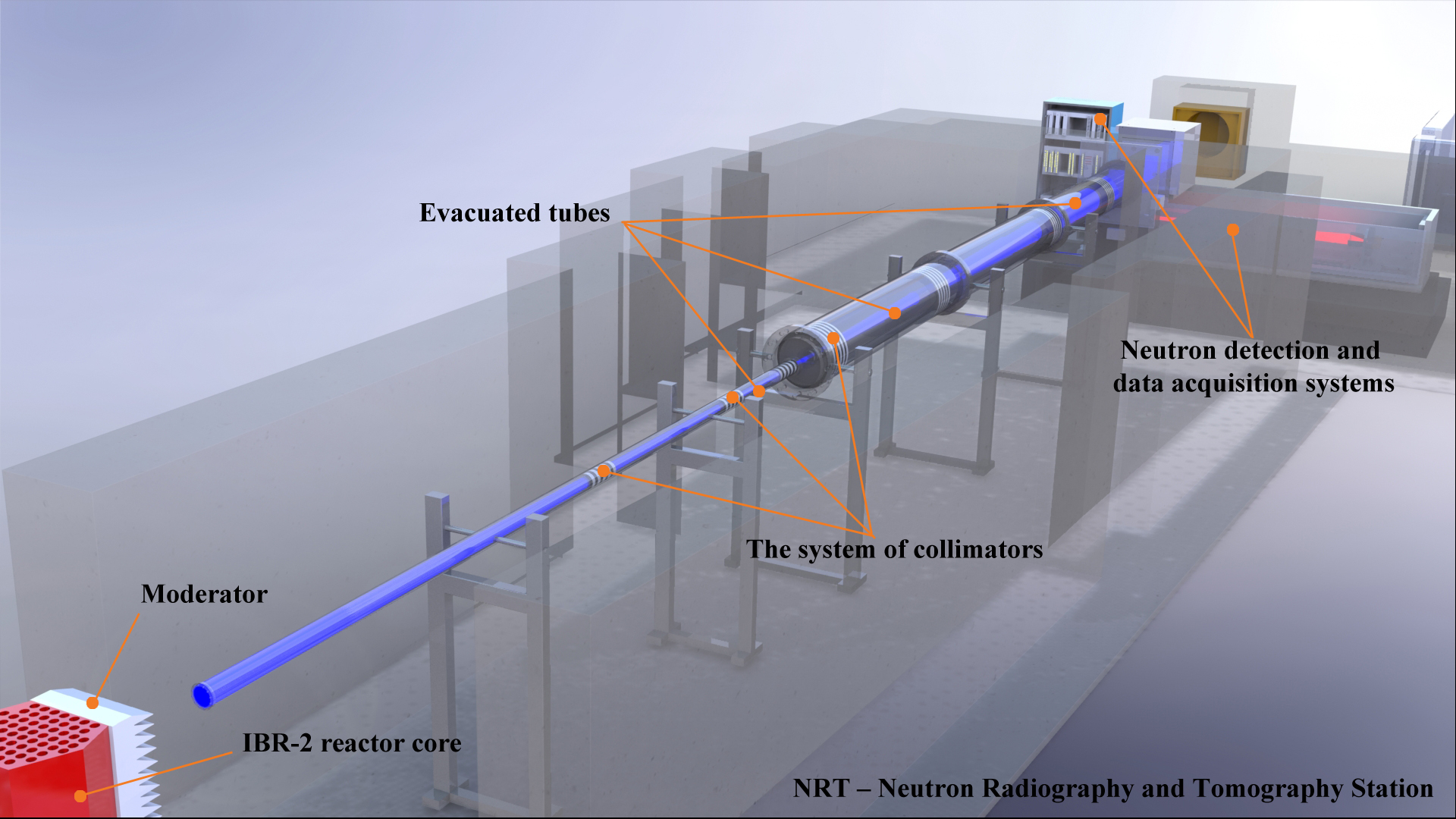

The experimental station for investigations using neutron radiography and tomography (NRT) is positioned on the beamline 14 of the IBR-2 reactor and is designed to study the internal structure of objects using neutron radiography and tomography.

Neutron radiography is a leader in the modern world among other types of non-destructive testing. In this technique, due to varying degrees of attenuation of the intensity of the neutron beam when passing through materials of different chemical composition, density and thickness of the components of the studied sample, information is obtained on the internal structure of the studied materials with a spatial resolution at the micron level. Neutron radiography is characterized as penetrating deeper into the thickness of the material under study compared to the complementary method of X-ray radiography and possesses advantages in the study of objects that simultaneously contain both light elements (such as hydrogen or lithium) and heavy elements.

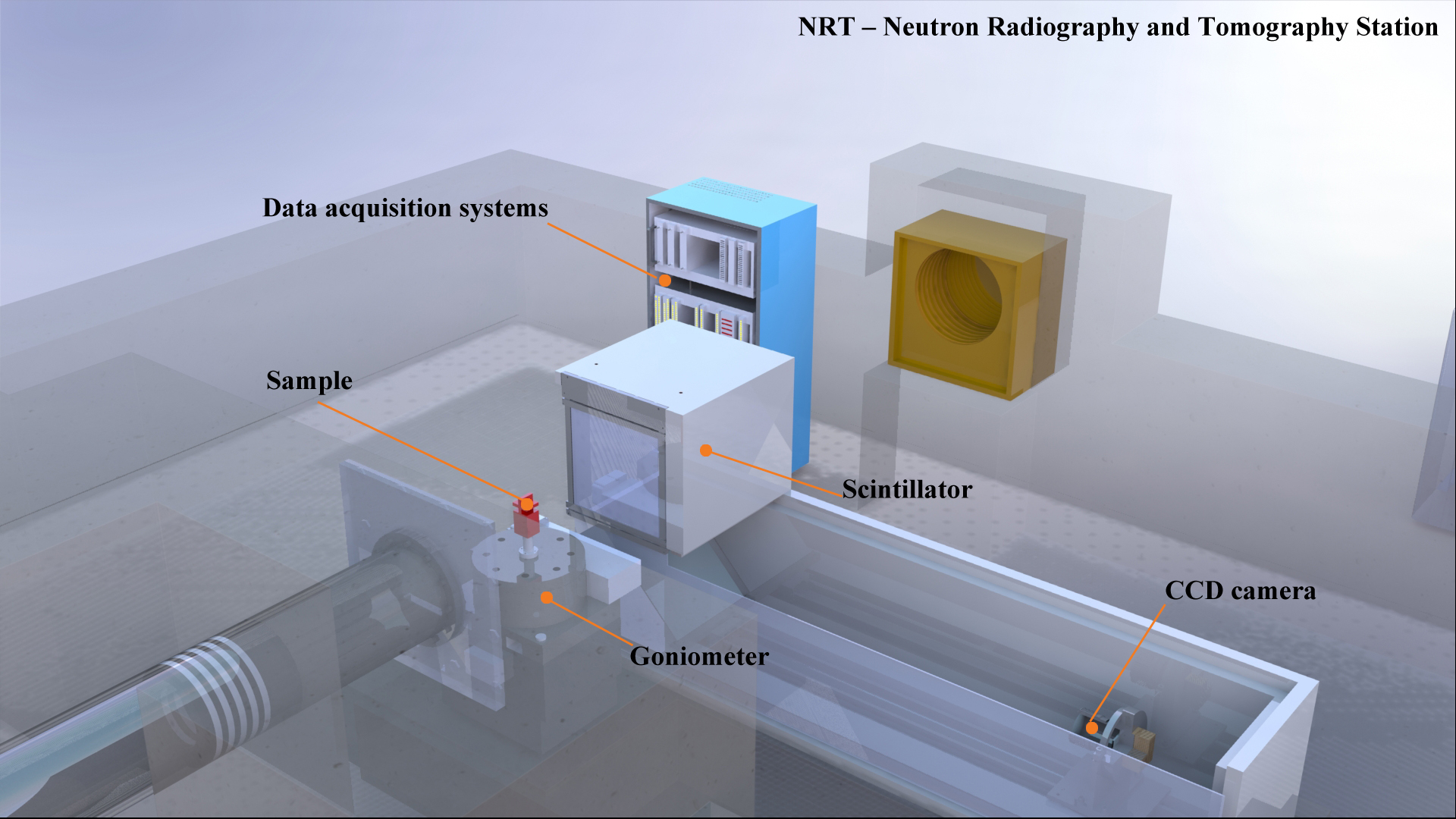

The main components of the NRT experimental facility are: a system of collimators that develops a neutron beam; goniometer; neutron registration and data acquisition system.

The system of collimators consists of three evacuated tubes with a total length of 18 m, inside which there are seven cylindrical collimators that produce an output neutron beam with dimensions of 200x200 mm.

The neutron beam, passing through the sample, experiences absorption and scattering on the internal components of the sample that allows to study the spatial distribution of chemical elements and their isotopes, internal cracks, chips, hidden structural elements and other features.

Neutrons that pass through the sample fall on the scintillator that converts them into visible light. The optical image falls on the CCD-chip of a highly sensitive video camera. The final spatial resolution of the detector system is 150 µm. The high neutron flux on the test sample determines the short exposure time (up to 10 seconds). For tomographic experiments, a goniometer with a minimum rotation angle of 0.010 is used. To get the full picture, the sample is rotated at 180° or 360° in 0.5° increments.

The neutron radiography and tomography methods are a powerful tool of non-destructive analysis, playing an important part in industrial and scientific research. The fundamental difference in the nature of neutron interaction with matter compared to X-rays provides additional benefits to neutron methods, including sensitivity to light elements, notable difference in contrast between neighboring elements or isotopes, high penetration into metals or heavy elements. All these features make neutron radiography and tomography highly demanded tools with a growing range of applications in industry, geophysics, paleontology, archeology and other various fields, including cultural heritage investigations. A neutron radiography and tomography facility operates at the IBR-2 high-flux pulsed reactor. The main parameters of this facility are listed below.

Main parameters L/D ratio 200-2000 Aperture diameter D Aperture - sample distance L 10 m Beam cross section (in the field of view of the camera) 20x20 cm2 CCD camera type HAMAMATSU S12101 Active pixels Number of pixels 2048x2048 Pixel Size (µm) 11 µm CCD chip area (mm) 9x9 Bit depth 16 Bits 6LiF/ZnS scintillator Gadox scintillator 132 µm

10-50 mm

Neutron flux

5.5(2)x106 n/cm2/c

Cooling method

Peltier effect

Characteristics of the scintillation screen

Spatial resolution

Image Processing

ImageJ, H-PITRE, VGStudio MAX 2.2 software

References

1. Kozlenko D.P., Kichanov S.E., Lukin E.V., Rutkauskas A.V., Bokuchava G.D., Savenko B.N., Pakhnevich A.V., Rozanov A.Yu., Neutron Radiography Facility at IBR-2 High Flux Pulsed Reactor: First Results, Physics Procedia 69, 87 – 91 (2015).

2. Kozlenko D. P., Kichanov S. E., Lukin E. V., Rutkauskas A. V., Belushkin A. V., Bokuchava G. D., Savenko B. N. Neutron radiography and tomography facility at IBR-2 reactor, Phys. Part. Nuclei Lett., 13: 346 (2016).

3. K.M. Podurets, S.E. Kichanov, V.P. Glazkov, E.S. Kovalenko, M.M. Murashev, D.P. Kozlenko, E.V. Lukin, E.B. Yatsishina “Modern Methods of Neutron Radiography and Tomography in Studies of the Internal Structure of Objects”, Crystallography Reports, 66, 2, 254-266 (2021)

4. B. Bakirov, I. Saprykina, S. Kichanov, R. Mimokhod, N. Sudarev, D. Kozlenko “Phase Composition and Its Spatial Distribution in Antique Copper Coins: Neutron Tomography and Diffraction Studies”, Journal of Imaging, 7, 8, 129 (2021).

5. A. El Abd, M. Taman, S.E. Kichanov, E. Hamad, К.M. Nazarov “Implementation of capillary penetration coefficient on water sorptivity for porous building materials: An experimental study”, Construction and Building Materials, 298, 123758 (2021).

6. S. Kichanov, I. Saprykina, D. Kozlenko, K. Nazarov, E. Lukin, A.Rutkauskas, B. Savenko, “Studies of Ancient Russian Cultural Objects Using the Neutron Tomography Method” J. Imaging, 4(2), 25 (2018)

7. I. Yu. Zel, M. Kenessarin, S.E. Kichanov, M. Balasoiu, D.P. Kozlenko, K. Nazarov, M. Nicu, L. Ionascu, A.C. Dragolici, F. Dragolici “Spatial distribution of graphite in cement materials used for radioactive waste conditioning: An approach to analysis of neutron tomography data”, Cement and Concrete Composites, 119, 103993 (2021)

8. S.E. Kichanov, D.P. Kozlenko, A.K. Kirillov, E.V. Lukin, B. Abdurahimov, N.M. Belozerova, A.V. Rutkauskas, T.I. Ivankina, B.N. Savenko “A structural insight into the Chelyabinsk meteorite: neutron diffraction, tomography and Raman spectroscopy study”, SN Applied Sciences, 1:1563 (2019).