Responsible for the facility

Zel Ivan

tel.+7 (49621) 6-49-69

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Main research areas:

- Crystalline and magnetic structure of functional materials under high pressure;

- Structural and magnetic phase transitions under high pressure;

- Dynamics of hydrogen-containing compounds under high pressure;

- Research of small sample volumes using neutron diffraction over a wide temperature range.

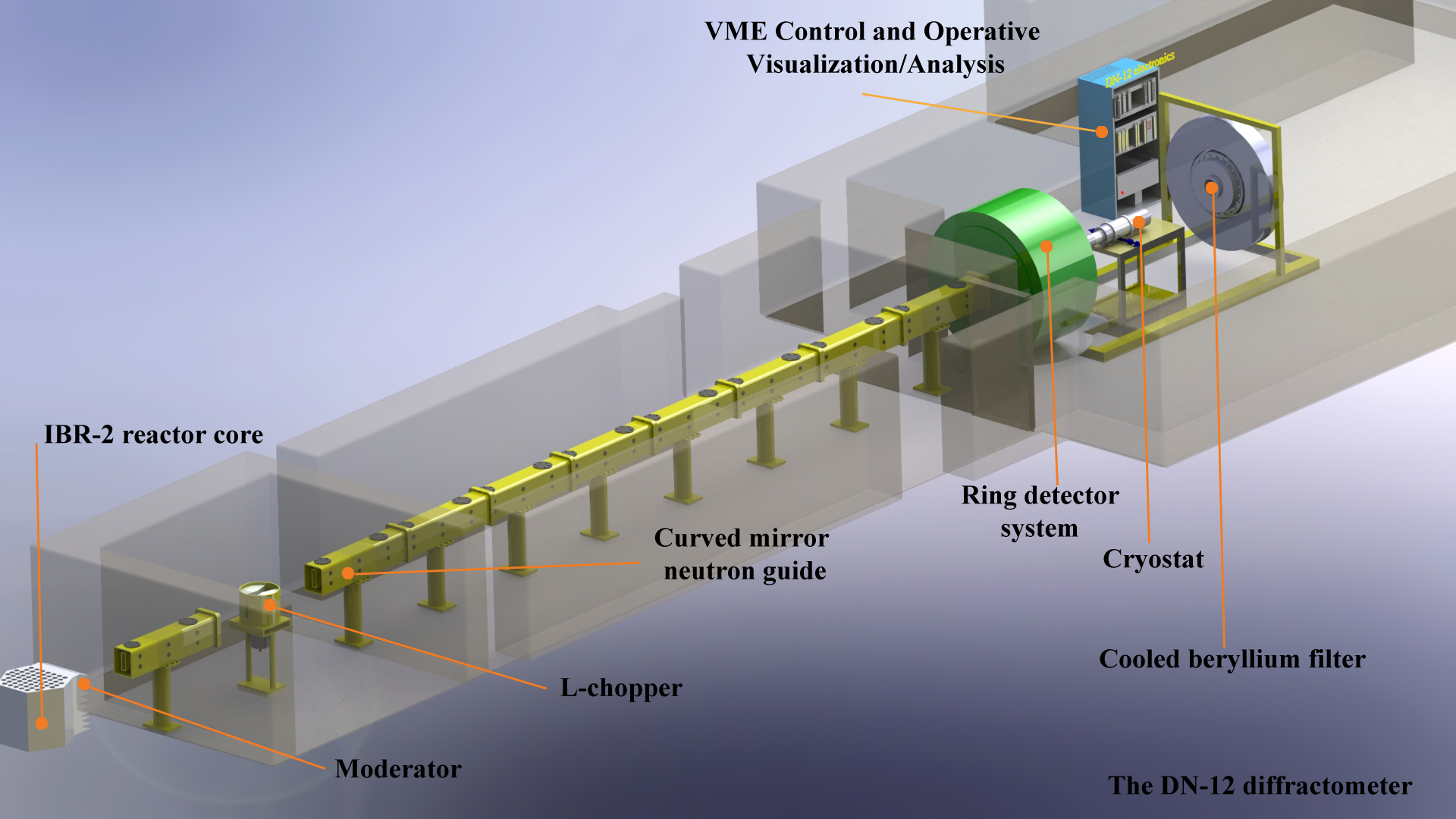

Main view of facility

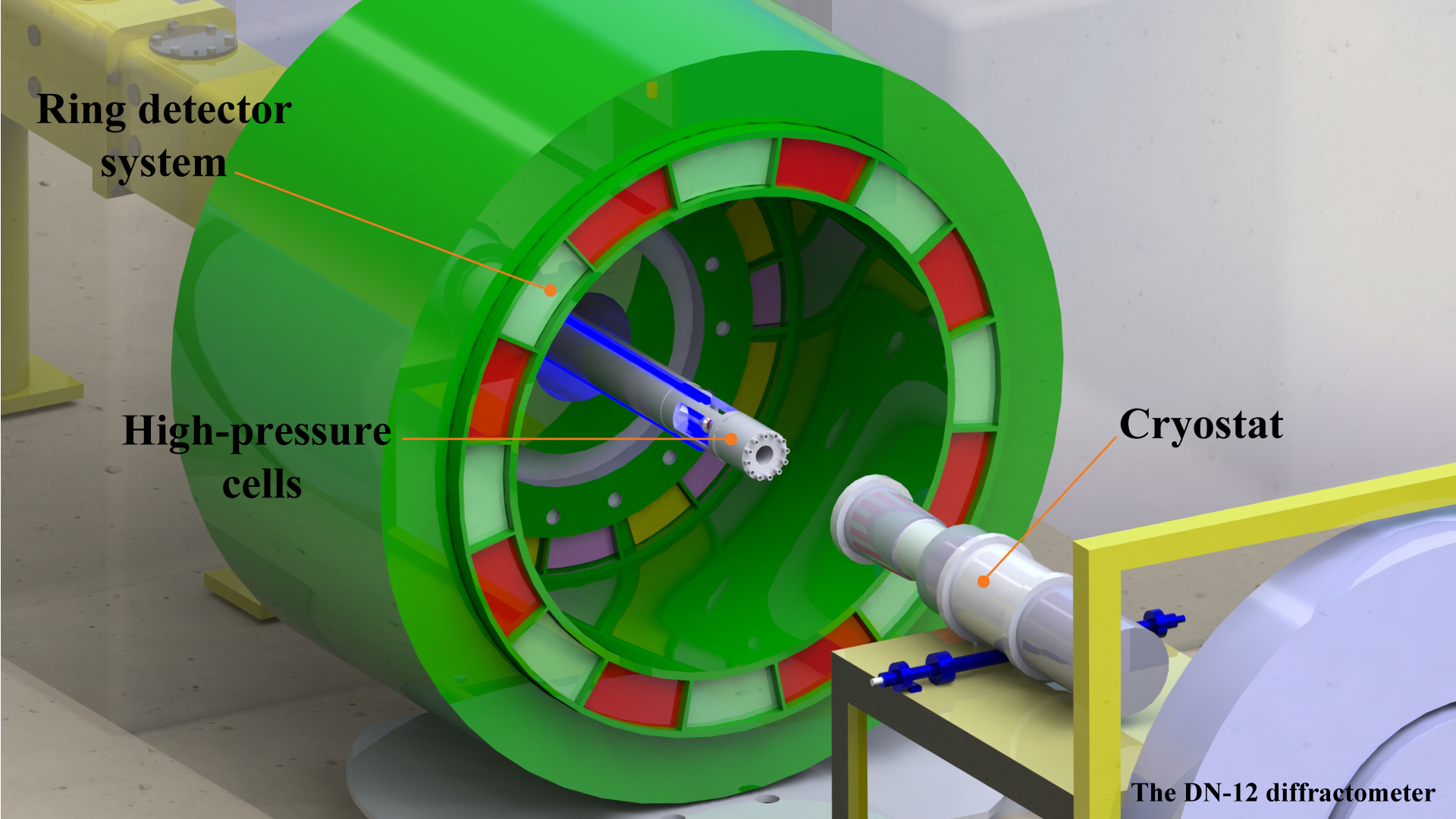

Sample environment

Description of DN-12

Recently, there has been significant progress in the research of materials exposed to extreme conditions. The impact of high pressure often leads to the occurrence of new physical phenomena in materials, including pressure-induced superconductivity, various changes in magnetic states, dielectric-metal transitions, spin crossover, structural and electronic phase transitions. In addition, research at high pressures opens up unique opportunities for studying the microscopic mechanisms of the formation of physical phenomena in functional materials as a result of analyzing the response of various properties to changes in structural parameters during crystal lattice compression. The nature of the interaction of neutrons with matter determines a range of advantages of neutron diffraction over the corresponding X-ray methods in structural research: high sensitivity to positions in the crystal structure of light atoms, such as hydrogen and oxygen, especially under conditions of structural disorder; the possibility of studying the magnetic structures of materials; high penetrating power. At the Frank Laboratory of Neutron Physics of the Joint Institute for Nuclear Research (Dubna, Russia) for more than a quarter of a century, experimental methods and techniques for neutron research at high pressures have been successfully developed at the high-flux pulsed reactor IBR-2. In the mid-1990s, a specialized DN-12 spectrometer was developed at IBR-2 jointly with the staff of the National Research Center “Kurchatov Institute” to carry out research using neutron diffraction, inelastic incoherent neutron scattering and high-pressure chambers with sapphire anvils in the range up to 7 GPa. This diffractometer is one of the few facilities in the world that allows to carry out such research, while samples of a record-low volume are used in experiments.

The DN-12 neutron diffractometer consists of the following main components: a drum-type neutron beam chopper to improve the background conditions on the test sample, a curved neutron guide on supermirrors in an evacuated casing 26 m long, a beam collimation system, a ring detector system in a protective casing, an electronic control system, registration and processing of neutron data. To provide low temperatures on the sample, a closed-cycle helium refrigerator is used that allows to carry out neutron experiments in the temperature range of 10–300 K. At the present time, a system of cooled magnets on superconducting windings is developed for the DN-12 spectrometer. This system will make it possible to carry out experiments in magnetic fields up to 5 T and low temperatures up to 10 K with high-pressure chambers with sapphire anvils.

Various types of compact high-pressure chambers with single-crystal sapphire anvils are used to implement experiments at high pressures at the DN-12 facility. Diffractometer experiments are carried out in axial geometry, when a falling collimated neutron beam passes through a sapphire single crystal anvil and scatters on the sample. Scattered neutrons are registered separately using each of the detector ring counters. A horizontal cryostat based on a closed-cycle helium refrigerator is used for low-temperature experiments in the range of 5–320 K. The design of the cryostat allows to cool high-pressure chambers with both sapphire and diamond anvils. The high-pressure chamber is loaded into a cryostat that makes it possible to study in detail the structures and magnetic phase diagrams of a wide range of objects at various temperatures and pressures.

Main characteristics 1. Neutron flux on the sample (with an average reactor power of 1.5 MW) 2·106 n/cm2/c 2. Distance: 3. Range: wavelengths scattering angles interplanar distances 0.6 – 12 Å 4. Resolution (Δd/d , d = 2 Å): for 2θ = 45° 0.03 5. Solid angle of the detector system 0.125 s 6. Sample volume 0.5 – 3 mm3 7. Pressure range: 8. Temperature range 10 – 320 K

moderator-sample

sample-detector

26.0 m

0.4 m

0.8 – 10 Å

45° – 135°

for 2θ = 90°

for 2θ = 135°

0.022

0.022

0 – 8 GPa

Sample environment:

A cryostat based on a closed-cycle helium refrigerator allows to carry out neutron diffraction experiments in the temperature range 10–320 K.

High-pressure chambers based on sapphire anvil technology allow to implement neutron diffraction experiments at high pressures up to 9 GPa.

A cooled beryllium filter allows to measure inelastic incoherent neutron scattering at high pressures, required for the research of the dynamics of atoms in crystals.

References:

- P. Kozlenko, S.E. Kichanov, E.V. Lukin, B.N. Savenko “High-Pressure Neutron Diffraction Study of the Crystal and Magnetic Structure of Materials at the Pulsed Reactor IBR-2: Current Opportunities and Prospects” Crystallography Reports, 66, 2, 303-313 (2021)

- P. Kozlenko, E. Burzo, P. Vlaic, S. E. Kichanov, A. V. Rutkauskas & B. N. Savenko “Collapse in ErCo2:Beyond the Limits of Itinerant Electron Metamagnetism” Sci. Rep. 5, 8620 (2015)

- M. Belozerova, S.E. Kichanov, Z. Jirák, D.P. Kozlenko, O. Kaman, E.V. Lukin, B.N. Savenko “The crystal and magnetic structure of nanostructured manganite La0.53Sr0.47MnO3 at high pressure”, Materials Chemistry and Physics, 262, 124310 (2021)

- Kozlenko D. P., Kichanov S. E., Lukin E. V., Dang N. T., Dubrovinsky L. S., Liermann H.-P., Morgenroth W., Kamynin A. A., Gridnev S. A., and Savenko B. N. “Pressure-induced polar phases in relaxor multiferroic PbFe0.5Nb0.5O3” Physical Review B, 2014, v.89, p.174107.