Responsible for the facility

Kruglov Aleksander

tel. +7 (49621) 6-47-89

e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Main research areas

- Research of internal stresses in structural materials and industrial products

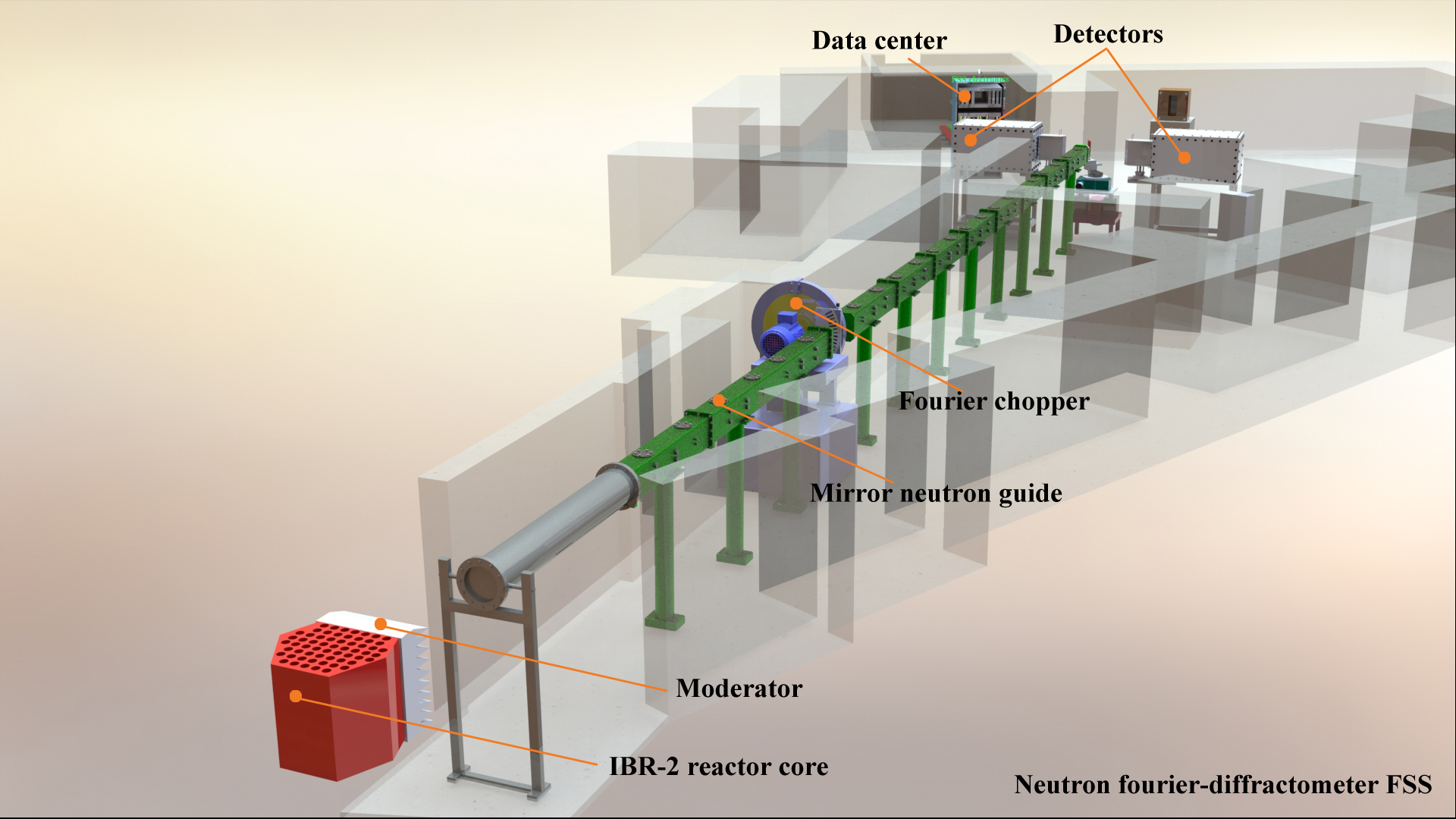

Facility layout

Main view of facility

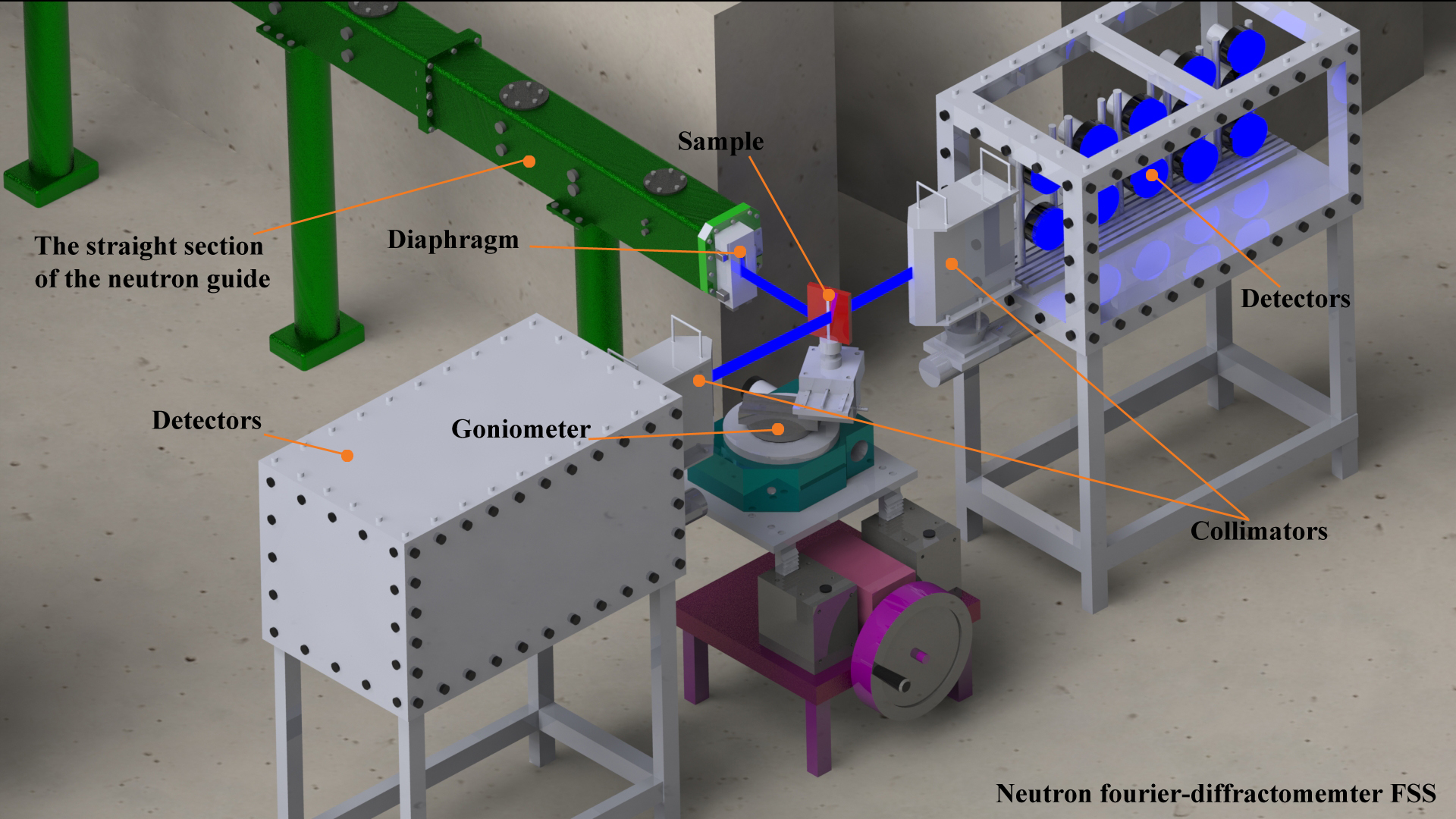

Sample environment

Description of FSS

Fourier diffractometer FSS on beamline 13 of the IBR-2 reactor is designed to investigate internal stresses in structural materials and industrial products using high-resolution neutron diffraction that allows to determine residual stresses in bulk samples with an accuracy of about 20 MPa. In addition to scientific research, an important area of scientific and methodological activity at FSS is the further development of the neutron correlation RTOF-technique for the analysis of elastic neutron scattering on crystals, as well as the development and testing of new detectors, detector electronics and data acquisition electronics.

The IBR-2 reactor is a pulsed neutron source with a water comb moderator, in which fast neutrons produced in the reactor core are moderated to thermal energies. Thus, thermal neutron pulses with a frequency of 5 Hz and a duration of ~350 μs are produced. To increase the luminosity of the diffractometer and to reduce the background level from fast neutrons and γ-rays, the initial neutron beam at FSS is produced using a vacuum mirror neutron guide that consists of two sections - a curved and a straight one.

In the gap of the neutron guide the following units are installed: a damper valve that provides prompt shutdown of the neutron beam and safe access to the main components of the facility, as well as a fast Fourier chopper that provides the required modulation of the neutron beam intensity. There are 1024 radial slots on the periphery of the chopper disk, similar slots are manufactured on the stator plate. Such a Fourier chopper provides modulation of the neutron beam intensity with a frequency of up to ~100 kHz, while achieving a rather small efficient width of the neutron pulse (about 10 μs) that determines the high level of resolution of this diffractometer.

A diaphragm is positioned at the exit from the straight section of the neutron guide that adjusts the height and width of the incident beam. The sample is positioned in the required position using a HUBER 4-axis goniometer with a load capacity of up to 100 kg. If required, the sample can be positioned in a high-temperature furnace. The detector system consists of two detectors mounted at 90 degrees to the incident beam. To isolate a small scattering volume of a few mm3 in the depth of the sample, in which permanent strain is measured, radial collimators with a spatial resolution of 2 mm are positioned in front of the 90-degree detectors. The automation system of the diffractometer allows to carry out local or remote control of the experiment, as well as to flexibly establish a measurement programme based on the specified scanning points in the sample.

High resolution and accuracy of registering small (of 10-3) relative changes in interplanar distances in the crystal lattice is achieved due to a special correlation technique - a combination of a fast Fourier chopper for modulating the intensity of the initial neutron beam and the RTOF-technique for data accumulation.

Basic parameters Curved neutron guide mirror, Ni/Ti coating (m=2) - length, m 17.32 - curvature radius, m 1900 Neutron beam size at the sample position (0 ÷ 10) ´ (0 ÷ 50) (variable), mm Moderator - sample distance, m 27.2 Chopper - sample distance, m 11.43 Fourier chopper (disk) high impact Al alloy - outer diameter, mm 540 - slot width, mm 0.7 - number of slots 1024 - max. rotation speed, rpm 6000 - max. beam modulation frequency, kHz 102.4 Thermal neutron pulse width: - in low resolution mode, µs 340 - in high resolution mode, µs 9.8 The neutron flux density on the sample (without 1.2×106 chopper), neutr./ cm2×с-1 Detectors (2q=±90°) 6Li, with time focusing Resolution of detectors Dd/d (d=1÷1.5 Å) 4×10-3 Dhkl range, Å 0.5 ÷ 3.5

Sample environment

- High temperature mirror furnace with operating temperature up to 1000 ºC;

- Radial collimators with a spatial resolution of 2 mm;

- 4-axis goniometer with a load capacity of up to 100 kg.

Publications

- Г.Д. Бокучава, А.А. Круглов, И.В. Папушкин, В.В. Журавлев, Т.Б. Петухова, С.М. Мурашкевич, Л.А. Трунтова, Н.Д. Зернин, Нейтронный фурье-стресс-дифрактометр FSS на реакторе ИБР-2: результаты модернизации и перспективы дальнейшего развития, Поверхность. Рентгеновские, синхротронные и нейтронные исследования, 2022, № 5, с. 3-13. https://doi.org/10.31857/S1028096022050077

- G. Bokuchava, A. Kruglov, I. Papushkin, V. Zhuravlev, A. Kustov, A. Chernikov, A. Sirotin, N. Zernin, L. Truntova, S. Murashkevich, T. Petukhova, A. Bulkin, Fourier stress diffractometer FSS at the IBR-2 pulsed reactor, European Conference on Neutron Scattering (ECNS 2019), July 1-5, 2019, St. Petersburg, Russia. http://ecns2019.com