Other works performed at the IBR-2

- Review on role of Aβ peptide in development of Alzheimer’s disease published in Natural Science Review journal

- Most stable structural phase of biocompatible zirconium dioxide found

- FLNP JINR researchers evaluated effect of rare-earth metals on cyanobacteria

- Assessment of chemical elements in soil in Romania

- On development of semi-interpenetrating polymer-micellar networks

- Peculiarities of charge-discharge processes in PW electrodes with different level of dehydration

- Gamma radiation-induced alterations in nanocrystalline titanium nitride particles

- Neutron diagnostics of nuclear reactor surveillance specimens

- Neutron scattering helps in developing burn wound dressings with desired properties

- Authors of USPEX from SKOLTECH on a visit to FLNP. New superconducting hydrides: predict, synthesize, and study

- Neutron scattering, membrane biophysics, and Alzheimer's

- Galfenol: studies of alloys for «energy harvesting»

- Preserving history captured in granite

- Neutrons reveal secrets of shape memory alloys

- Fullerenes in the fight against amyloids: under scrutiny of neutrons

- Magnetic textiles for biocatalysis. Neutron investigations help to explain the structural features of a complex nanocomposite material.

Using neutron scattering techniques, staff members of FLNP JINR study the structure of magnetic cotton fabrics obtained in a new ecological way.

Iron oxide nanoparticles: magnetic sorbents and nanozymes

In recent decades, the popularity of nanoparticles has not waned: chemists, physicists and biologists use them in numerous investigations, they are in demand in the pharmaceutical and biotechnological industries, in medicine and ecology. The unusual physical and chemical properties of these tiny particles (1-100 nm) are related to the manifestation of quantum size effects in the near-surface area. Both native (with unmodified surface) and immobilized (with extra functional coatings) nanoparticles are used.

By processing the surface of nanoparticles and embedding them into other materials, scientists obtain substances with the desired properties. Of particular interest, undoubtedly, are magnetic nanoparticles, the behavior of which can be controlled using an external magnetic field. Such magnetic iron oxide nanoparticles and materials based on them, such as nanosorbents, are used in the chemical and oil industries for data storage, environmental pollution monitoring, assessment of product quality, biomedical imaging, diagnostics and targeted drug delivery. They combine the properties of organic and inorganic materials, demonstrating not only sorption properties, but also the ability to control the absorption process using a magnetic field.

The biocatalytic activity of iron oxide nanoparticles discovered 15 years ago has resulted in a new cycle of their research for possible use as artificial enzymes or nanozymes. Such nanoparticles mimic the behavior of enzymes (special proteins that speed up biochemical reactions by several orders of magnitude) and can replace them in various applications of science and technology. Due to the peroxidase activity, iron oxide nanoparticles can be successfully used, for instance, in the production of cheap chemical and biosensors for immunoanalysis.

How to “weave” the desired magnetic textile?

“Embedding magnetic iron oxide nanoparticles into various artificial and cotton fabrics is of great interest to researchers. For this purpose, the deposition of magnetic nanoparticles on various textile products that are in contact with magnetic fluids or liquid suspensions of magnetic nanoparticles is used. The process of producing magnetic nanocomposites can be controlled using an external magnetic field, the required concentration and structure of the deposited material can be selected. In turn, the method of immobilization of magnetically sensitive nanoparticles (production of extra functional coatings that modify the surface of nanoparticles) makes it relatively easy to isolate them from large reaction volumes and hard-to-treat samples,” JINR FLNP staff member Mikhail Avdeev said that represents the international research team*.

How to produce magnetic textiles from cotton fabric? For this implementation, scientists embedded magnetite nanoparticles and their aggregates into cotton fabric in two ways. In the first case, the fabric was treated with magnetic fluid stabilized with perchloric acid in methanol and was dried. During the second treatment, the synthesis of iron oxide nanoparticles was carried out in a liquid solution with textiles, accompanied by exposure to microwave radiation, followed by drying (Fig. 1).

Fig. 1. Cotton textile modified with magnetic iron oxide nanoparticles in two ways: (upper row) textile treatment with magnetic fluid stabilized with perchloric acid in methanol; the concentration of iron oxide in the original magnetic fluid is indicated; (bottom row) synthesis of iron oxide nanoparticles in liquid solution with textiles of extra exposure to microwave radiation; the mass fraction of iron sulfate in the initial aqueous solution is indicated.

The production of magnetic nanocomposites implies their thorough investigation, since any structural changes in nanoparticles affect the properties of new materials. For this implementation, researchers use an entire range of available methods. JINR scientists together with colleagues used X-ray and neutron analysis techniques to study the structure of the synthesized magnetic textile (Fig. 2). They carried out experiments on small-angle neutron scattering on the YuMO spectrometer of the JINR IBR-2 basic facility and obtained small-angle X-ray scattering data on the DESY synchrotron radiation source (Germany).

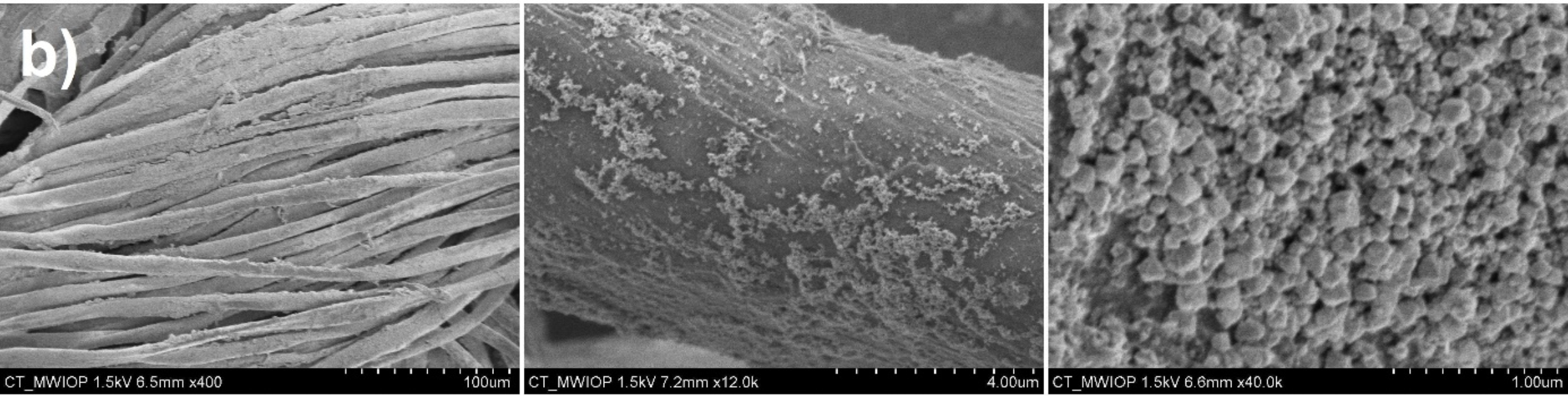

Fig. 2.1. Structural characterization of cotton textiles embedded with iron oxide nanoparticles: (upper row) images of the scanning electron microscope for the microwave-modified textile; the original 20% aqueous solution of ferrous sulfate was used (400, 12000, and 40000 times)

Fig. 2.2. Structural characterization of cotton textiles embedded with iron oxide nanoparticles: experimental small-angle X-ray and neutron scattering curves for original and modified textiles

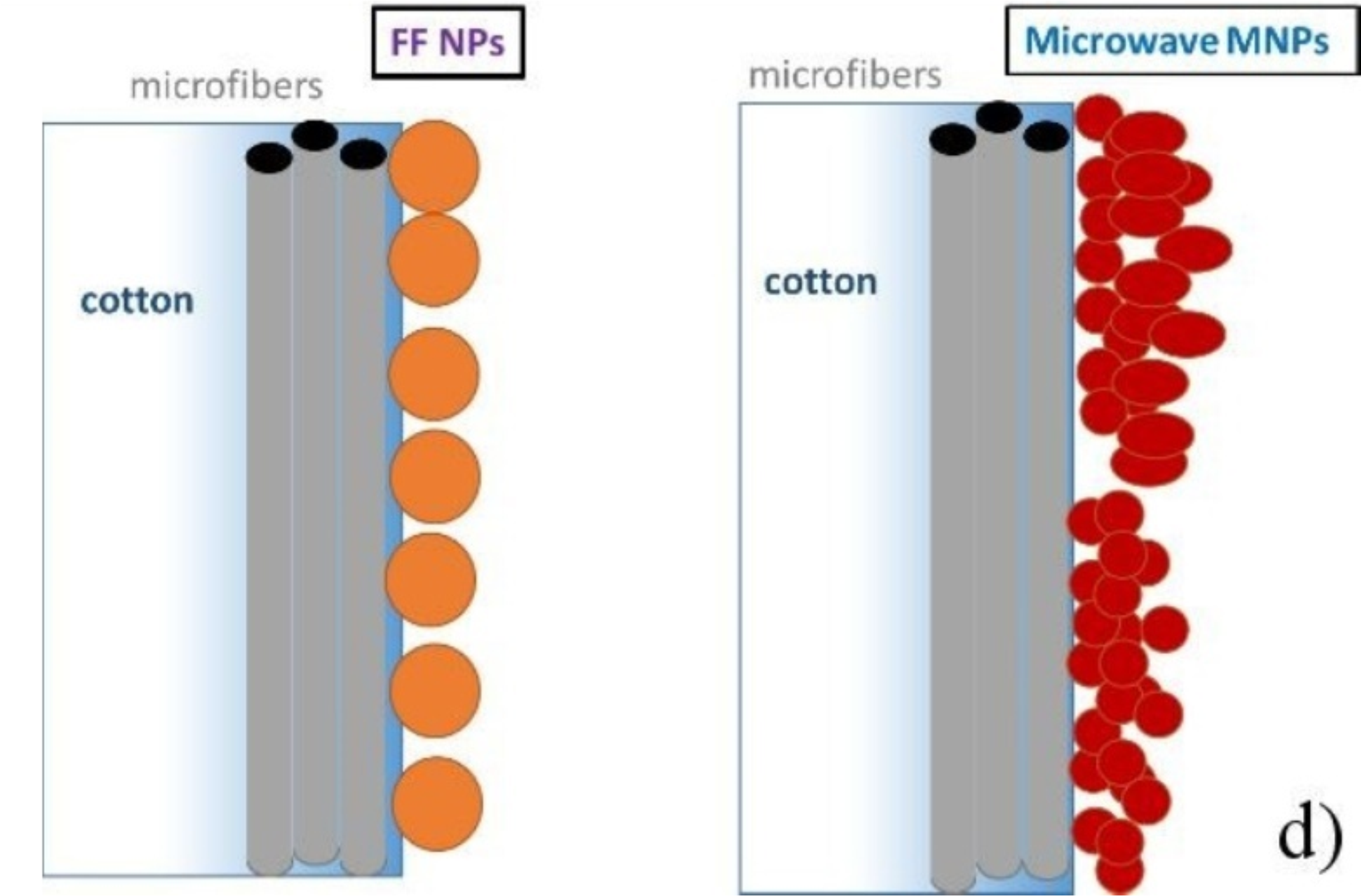

Fig. 2.3. Structural characterization of cotton textiles embedded with iron oxide nanoparticles: schematic of the structural organization of a magnetic textile prepared in two different ways

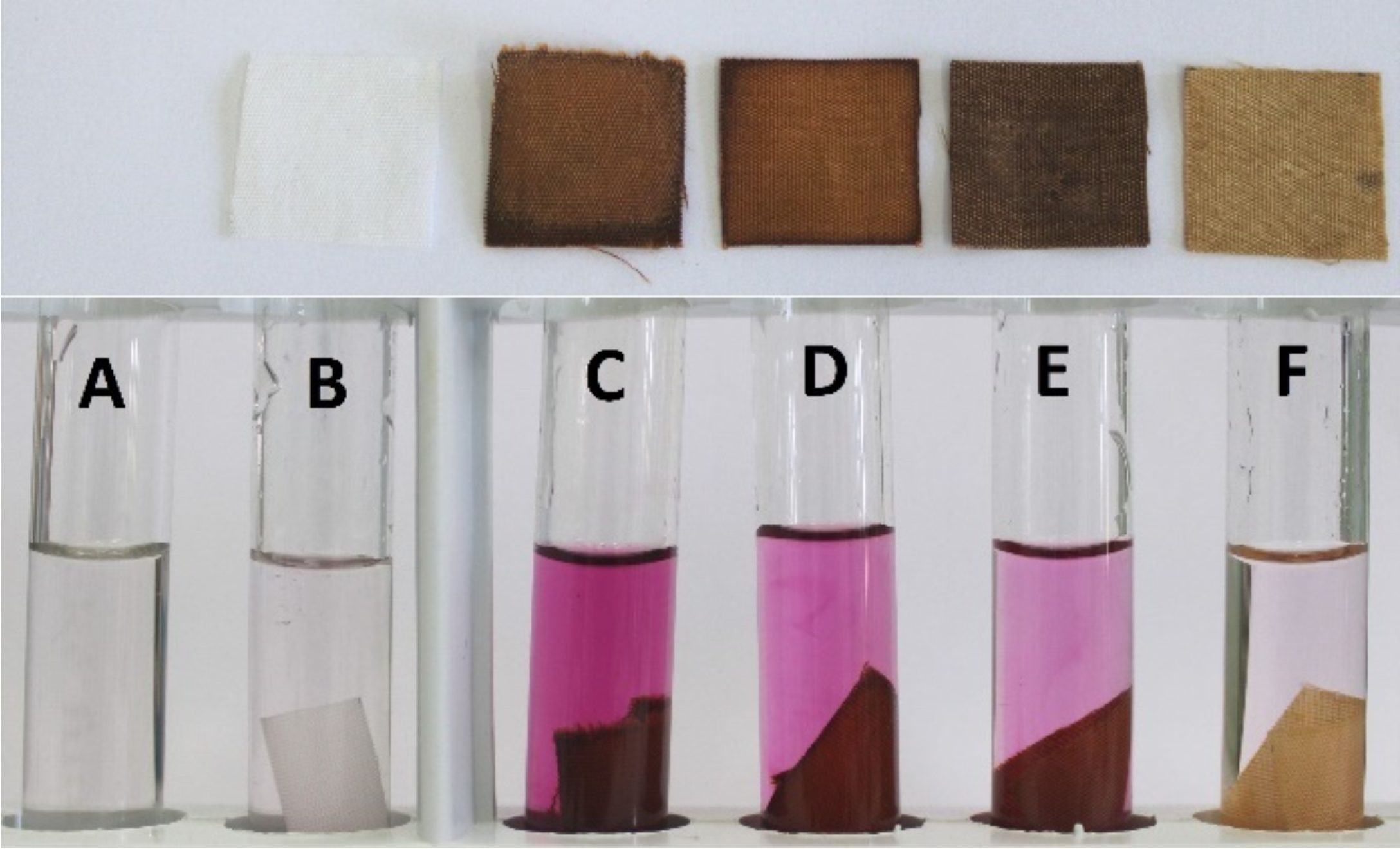

“We studied the nanozyme deposited on the tissue: the obtained structural data related to the magnetic properties of tissues,” Mikhail Avdeev explained. Based on the results of small-angle scattering using different contrast capabilities of X-ray and neutron radiation, scientists have identified different micro- and nanostructures in two types of produced magnetic textiles. The catalytic activity, similar to peroxidase, was also different in the obtained tissues. It was determined by the decolorization of a standard solution of crystal violet with a substrate (N-sulfate salt) at hydrogen peroxide (Fig. 3).

Fig. 3. Demonstration of the peroxidase-like activity of magnetic textiles using DPD as N,N-Diethyl-p-phenylenediamine (DPD) substrate. From left to right: A - control solution; B - control solution with cotton textiles; C, D - solution with samples of modified textiles produced using microwave radiation (ferrous sulfate concentration in the initial solution 20% and 10%); E, F - solution with samples of modified textiles prepared using methanol-based magnetic fluids (iron oxide concentration in the initial solution 10 mg/ml and 1 mg/ml)

The ease of embedding iron oxide nanoparticles into fabric and the low cost of the materials used open up wide opportunities for their use, for instance, as magnetic filters, for decolorization and decomposition of organic dyes and pollutants, as scientists believe.

* I.Safarik, J.Prochazkova, M.A.Schroer, V.M.Garamus, P.Kopcansky, M.Timko, M.Rajnak, M.Karpets, O.I. Ivankov, M.V. Avdeev, V.I. Petrenko, L.Bulavin, K.Pospiskova, Cotton Textile/Iron Oxide Nanozyme Composites with Peroxidaselike Activity: Preparation, Characterization, and Application, ACS Applied Materials & Interfaces 2021, 2021, 13, 23627−23637. https://doi.org/10.1021/acsami.1c02154

Olga Baklitskaya-Kameneva